Innovation with Iron

At RIFT, innovation and sustainability beautifully come together to revolutionize the energy world. The startup, born from the student team SOLID at TU Eindhoven, develops a circular and environmentally friendly fuel based on iron powder. This technology allows industries and district heating networks to drastically reduce their CO₂ emissions while effectively utilizing existing infrastructure.

The story of RIFT (Renewable Iron Fuel Technology) seems like a series of fortunate coincidences. CTO Vincent Seijger, originally trained as a maritime officer, decided to combine his shipping background with his passion for sustainability. For his master’s thesis in Sustainable Energy Technology at TU Eindhoven, he participated in a research project on the feasibility of iron as fuel for ships. Conclusion: due to high reliability requirements, shipping is not yet ready for this technology, but the technique is perfectly applicable on land.

Innovative and Efficient Concept

Seijger explains: “Iron powder is not only widely available but also offers a unique opportunity to make energy circular. When iron powder is burned, heat is released, and the only residue – rust – can be converted back into iron using hydrogen. RIFT developed two essential systems: an iron fuel boiler for heat production and a production system to recycle rust. Our concept is innovative and efficient and addresses the urgent need for sustainable solutions for industrial heat production, which is responsible for 20 percent of global greenhouse gas emissions.”

“Our concept addresses the urgent need for sustainable solutions for industrial heat production.”

Vincent Seijger

CTO, RIFT

“Our concept addresses the urgent need for sustainable solutions for industrial heat production.”

Flexible Solution

The process is as simple as it is ingenious: iron powder is burned in a special boiler, releasing heat and producing rust. This heat can be used for industrial applications such as food production, paper manufacturing, and district heating networks. The rust is then transported to a production system, where it is converted with hydrogen into regenerated, “recharged” iron powder. This powder can be reused as fuel, making the process fully circular. Because iron powder is easy to transport — by truck, train, or ship — the technology offers a flexible solution that doesn’t rely on expensive infrastructure like hydrogen pipelines.

Plug-and-Play Solution

In Helmond, RIFT started a pilot project in 2021 together with energy company Ennatuurlijk, integrating the boiler system into an existing district heating network. The system supplied CO₂-neutral heat to hundreds of households — a first in the Netherlands. This proves that the technology works not only in theory but is also practically applicable on a larger scale. Moreover, RIFT addresses a significant societal challenge. For many industrial companies, existing alternatives such as electricity or hydrogen are not feasible due to technical or financial constraints. RIFT offers these companies a plug-and-play solution that can significantly reduce their dependence on fossil fuels.

The process is as simple as it is ingenious.

Het proces is even eenvoudig als geniaal.

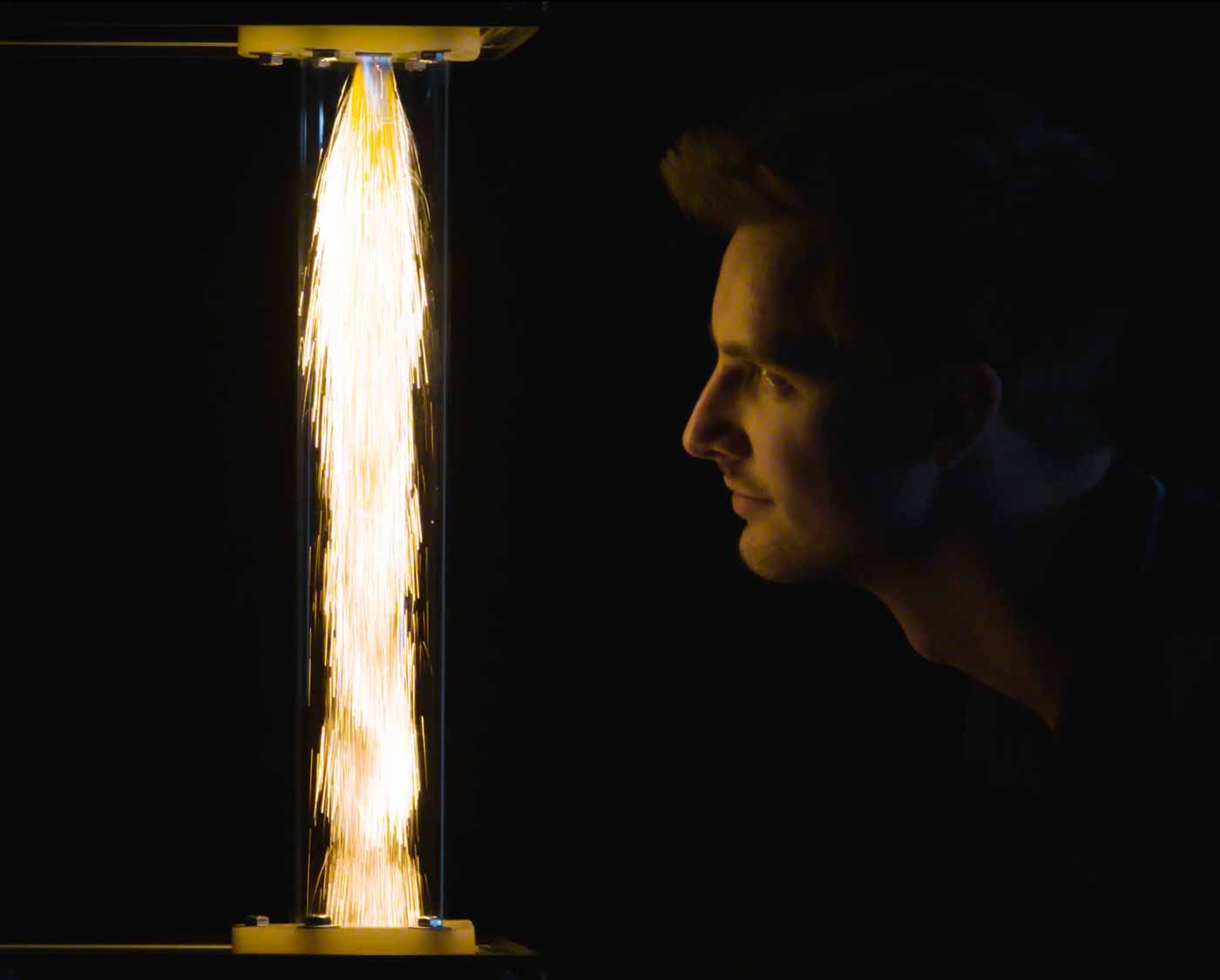

Test Setup in Arnhem

At Cleantech Park Arnhem, the regeneration concept was further developed. Here, RIFT focuses on regenerating rust back into iron using hydrogen. This takes place at the Connectr Energy Demo Field, where sustainable innovations are tested and showcased.

Seijger: “The choice for Arnhem was strategic: the city has a strong network of parties enthusiastic about sustainable technologies. Our location at the Energy Demo Field in Cleantech Park Arnhem is ideal for our pilot. In this industrial environment, we can test under realistic conditions.”

Collaboration as a Building Block for Innovation

RIFT’s growth would not have been possible without the drive and trust of passionate partners. “Cleantech Park Arnhem plays a key role in this,” says Vincent Seijger. “This business park, focused on sustainable energy innovations, provided us not only with a physical place to test and develop our technology but also access to a network of experts and facilities. Thanks to the flexibility and support of parties like Connectr, Veolia, Nedstack, HyGear, and the park management, permits were arranged quickly, significantly speeding up the process. This allowed us to get our production system — a 12-meter-high tower — operational in record time.”

A Sustainable Future

International collaboration, such as with Veolia, enables RIFT to think beyond the Netherlands alone. The combination of local expertise and international knowledge shows how innovation thrives best within a network of strong partners. This cooperation symbolizes Cleantech Park Arnhem’s role as an incubator for green innovations.

At Cleantech Park Arnhem, innovations for a cleaner future come to life. This is the perfect place for startups, established companies, government bodies, and educational institutions collaborating on clean technologies for the energy transition and circular economy. Join our active community of forward-thinking businesses today.